Gemeinsam mit einem internationalen Konsortium realisieren wir regelmäßig Joint Partner Projekte zu verschiedenen Leichtbau-Forschungs- und Entwicklungsfragen.

Treiben Sie Ihre Entwicklung effizient voran!

Gemeinsam mit einem internationalen Konsortium realisieren wir regelmäßig Joint Partner Projekte zu verschiedenen Leichtbau-Forschungs- und Entwicklungsfragen.

Treiben Sie Ihre Entwicklung effizient voran!

〉〉 Detaillierte, vorwettbewerbliche Untersuchung von Leichtbauwerkstoffen, -systemen oder -prozessen

〉〉 Verknüpfung von technischem Know-How und Marktwissen

〉〉 Kosteneffektives Budget basierend auf gemeinsamer Kostenteilung

〉〉 Kontakt zu einem breiten Netzwerk von industriellen Akteuren

Insights into emerging battery storage technologies and their impact on design factors for battery casings

Kick-Off: September 11th, 2024

Do you know…

What you‘ll get:

Expert assessment and evaluation of future battery technologies and their impact on requirements for material and design of battery casings.

If you are interested and would like to receive more information, please get in touch with:

Philipp Fröhlig

Head of Industrial Services | AZL Aachen GmbH

Phone: +49 241 475 735 14

Mobile: +49 176 80488799

Email: philipp.froehlig@azl-aachen-gmbh.de

Techniques for prediction of cell- and casing behaviour after the initial trigger event for thermal propagation

Kick-Off: September 11th, 2024

Do you know…

What you‘ll get:

The project provides know-how and predictive methods for the events happening after a first thermal runaway of a battery cell.

If you are interested and would like to receive more information, please get in touch with:

Philipp Fröhlig

Head of Industrial Services | AZL Aachen GmbH

Phone: +49 241 475 735 14

Mobile: +49 176 80488799

Email: philipp.froehlig@azl-aachen-gmbh.de

Potentials for composite materials and technologies in the energy transition market

Kick-Off: September 12th, 2024

Electric motors are playing an increasingly important role, especially for future mobility. High-speed permanent magnet motors offer several advantages, including high power density and efficiency.

Did you know?

What you‘ll get:

Expert assessment and evaluation of potentials for composite materials and technologies in the field of rotor sleeves for high-speed electric motors.

If you are interested and would like to receive more information, please get in touch with:

Philipp Fröhlig

Head of Industrial Services | AZL Aachen GmbH

Phone: +49 241 475 735 14

Mobile: +49 176 80488799

Email: philipp.froehlig@azl-aachen-gmbh.de

Potentials for composite materials and technologies in the field of air mobility and small/medium sized wind energy systems

Kick-Off: September 18th, 2024

Did you know?

What you‘ll get:

Expert assessment and evaluation of potentials for composite materials and technologies in the field of propellers and small to medium-sized rotors.

If you are interested and would like to receive more information, please get in touch with:

Philipp Fröhlig

Head of Industrial Services | AZL Aachen GmbH

Phone: +49 241 475 735 14

Mobile: +49 176 80488799

Email: philipp.froehlig@azl-aachen-gmbh.de

*bitte beachten Sie, dass alle Projektinformationen aufgrund der Internationalität der Projekte nur auf Englisch zur Verfügung stehen.

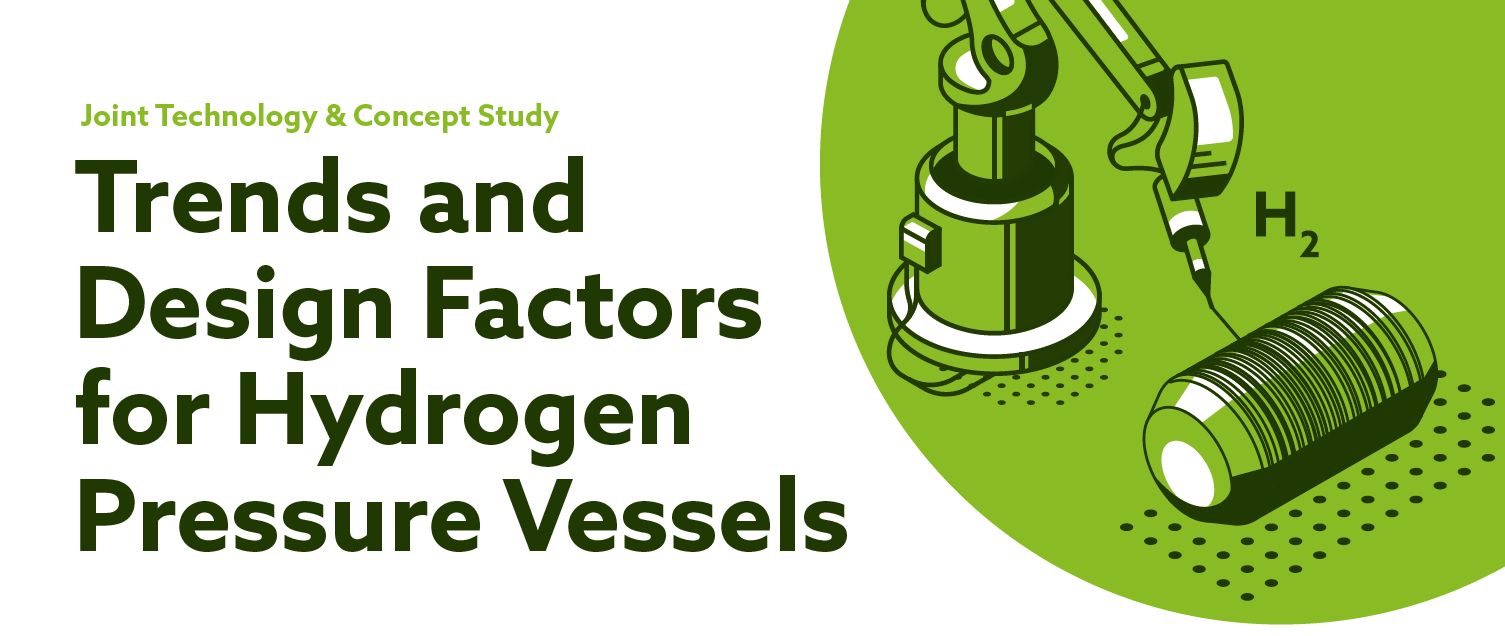

| Download the flyer with a short description “Trends and Design Factors for Hydrogen Pressure Vessels” |

| Download the flyer with detailed information “Trends and Design Factors for Hydrogen Pressure Vessels” |

If you are interested and would like to receive more information, please get in touch with:

Philipp Fröhlig

Head of Industrial Services | AZL Aachen GmbH

Phone: +49 241 475 735 14

Mobile: +49 176 80488799

Email: philipp.froehlig@azl-aachen-gmbh.de

*bitte beachten Sie, dass alle Projektinformationen aufgrund der Internationalität der Projekte nur auf Englisch zur Verfügung stehen.

| Download the flyer with the key facts on the Joint Partner Project “Cell-to-Pack Battery Casings” |

If you are interested and would like to receive more information, please get in touch with:

Philipp Fröhlig

Head of Industrial Services | AZL Aachen GmbH

Phone: +49 241 475 735 14

Mobile: +49 176 80488799

Email: philipp.froehlig@azl-aachen-gmbh.de

| Download the flyer with the key facts on the Joint Partner Project “Lightweight Tailgate” |

If you are interested and would like to receive more information, please get in touch with:

Philipp Fröhlig

Head of Industrial Services | AZL Aachen GmbH

Phone: +49 241 475 735 14

Mobile: +49 176 80488799

Email: philipp.froehlig@azl-aachen-gmbh.de

*bitte beachten Sie, dass alle Projektinformationen aufgrund der Internationalität der Projekte nur auf Englisch zur Verfügung stehen.

© 2024 AZL Aachen GmbH. All Rights Reserved.

Expertise/ background in:

Production and development of composite parts

Materials: thermoset and thermoplastic resins, continuous fiber composites, metals and plastic-metal hybrids

Process: prepreg, autoclave, resin infusion, RTM, milling, tooling, joining, quality assurance

Design: CAD design and design to process

Networking: Matchmaking with academic and industrial partners

I will support you in: