About us

Who are we?

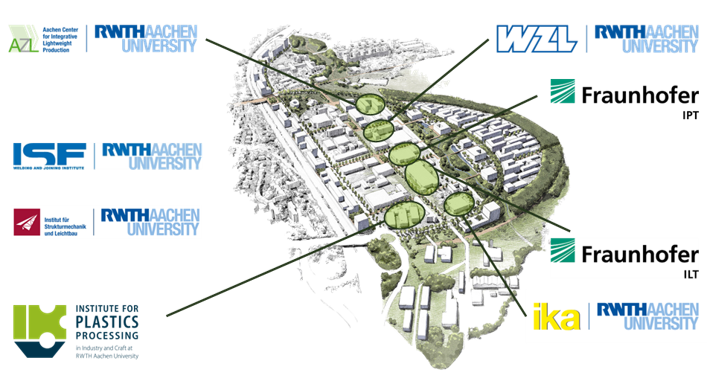

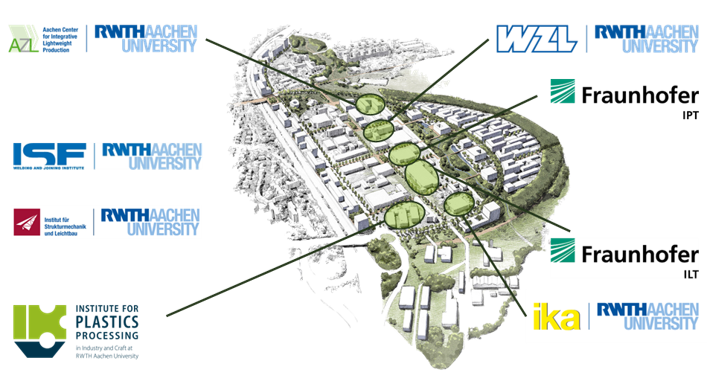

Partnering closely with the RWTH Aachen University, one of the worldwide leading universities in the field of production technology, AZL Aachen GmbH is specialized in composite-based lightweight technologies. AZL Aachen GmbH is supporting its customers as the interdisciplinary and holistic solution provider to analyze, understand and develop their products, processes and markets. The AZL offers a platform as well as projects to exchange knowledge and to effectively drive innovation by sharing effort. The industrial services include studies and benchmarks, technology advisory as well as development projects. For this, AZL Aachen GmbH uses its strong network at the RWTH Aachen Campus, which is one of the biggest research landscapes in Europe for enterprises and research institutions. At the Campus, 750 scientists and 1,200 student workers from 8 Institutes work on tomorrow’s technologies for lightweight production. AZL Aachen GmbH is partnering with these institutes covering the fields of plastics and composite materials (IKV), production technology (WZL, IPT, ILT, ISF), quality assurance and production-integrated measurement technology (WZL), lightweight design (SLA) and automotive production (IKA)

* Explanation of the institute´s abbreviations:

IKV – Institute of Plastics Processing in Industry and the Skilled Crafts

WZL – Laboratory for Machine Tools and Production

IPT – Fraunhofer Institute for Production Technology

ILT – Fraunhofer Institute for Laser Technology

ISF – Welding and Joining Institute

SLA – Institute for Structural Mechanics and Lightweight Design

With the AZL Partnership, the AZL Aachen GmbH enables the close cooperation between the lightweight industry and the research institutes of RWTH Aachen Campus along the whole value chain. The AZL Partner Network consists of more than 80 industrial partners representing the entire lightweight production value chain from the raw material producer, over molders, manufacturing equipment suppliers, Tier 1 and Tier 2 to OEMs, from SMEs to large multinational corporations, from Germany to Mexico, China or Japan, from 21 different countries in total. In five different workgroups, the AZL Partner Companies are working and exchanging on pre-competitive topics to drive composite and lightweight production.

* Explanation of the institute´s abbreviations:

IKV – Institute of Plastics Processing in Industry and the Skilled Crafts

WZL – Laboratory for Machine Tools and Production

IPT – Fraunhofer Institute for Production Technology

ILT – Fraunhofer Institute for Laser Technology

ISF – Welding and Joining Institute

SLA – Institute for Structural Mechanics and Lightweight Design

Quick Links

Contact Details

- +49 241 475735 0

- +49 241 475735 18

- info@azl-aachen-gmbh.de

-

Campus Boulevard 30

Building Part 3B, 4th Floor

52074 Aachen, Germany

© 2024 AZL Aachen GmbH. All Rights Reserved.