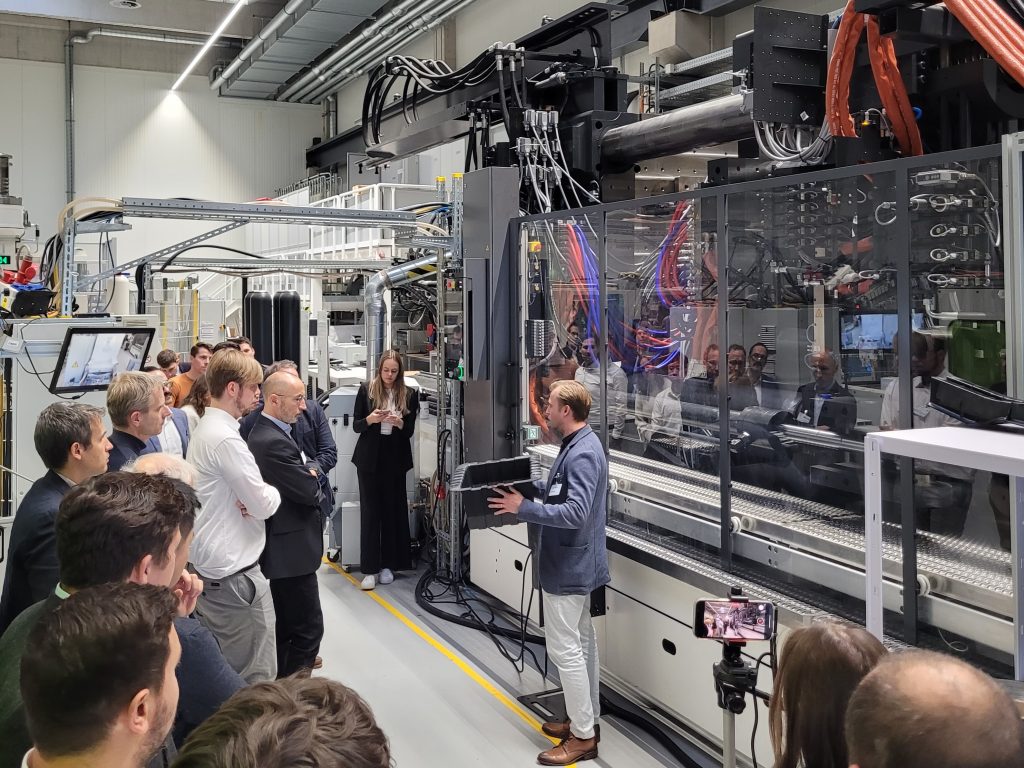

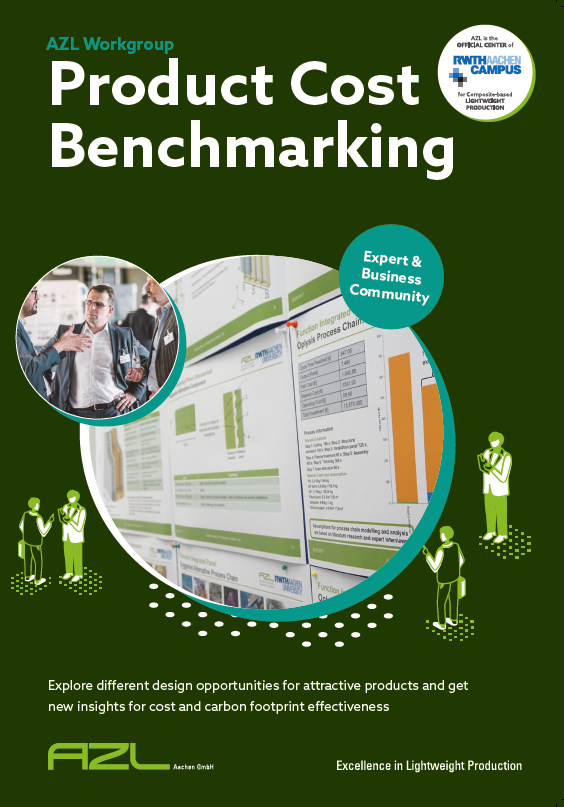

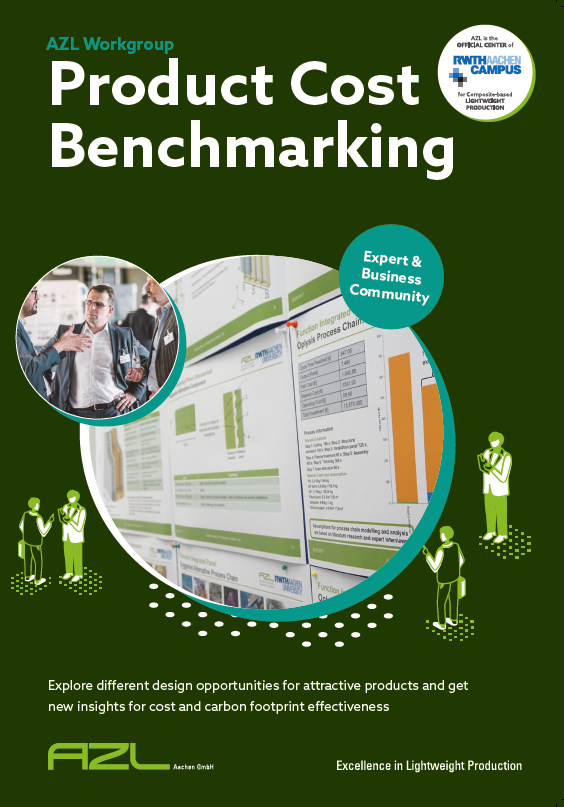

AZL founded the workgroup “Product Cost Benchmarking” at the end of February 2020. With the new workgroup format, the AZL is now focusing even more strongly on joint business case development. Together with more than 80 Partner Companies and experts from the RWTH Aachen University target markets and applications for composite-based multi-material technologies are regularly analyzed in live meetings on site and with cost analyses as a basis for joint technology developments.

So far, 15 composite components have already been analyzed with regard to their market potential, process chains and process steps as well as their product cost structure and cost drivers. These include components such as automotive bonnet and tailgate, battery housing, aircraft trolley, wind turbine blades or hockey stick. With this meeting format, the product cost benchmarks are jointly developed and co-designed by the participating companies.

Download the Flyer with all the information on the Workgroup

“Product Cost Benchmarking”